Under the perpetual inventory system, an entity continually updates its inventory records in real time. Perpetual inventory is by far the preferred method for tracking inventory, since it can yield reasonably accurate results on an ongoing basis, if properly managed. Employing job costing enables businesses to assign costs to each production run or batch of products, facilitating a comprehensive tracking of expenditures specific to each job. The resulting data can then be leveraged to make informed pricing decisions, optimize production processes, and allocate resources effectively. With numerous accounting methods and costing strategies that manufacturing businesses can use, it is always important to ensure that cash flow is maintained to avoid hiccups during production. Manufacturing business owners can also consider financing options such as invoice factoring to maintain a streamlined flow of money in their operations regardless of the market outlook.

WIP inventory

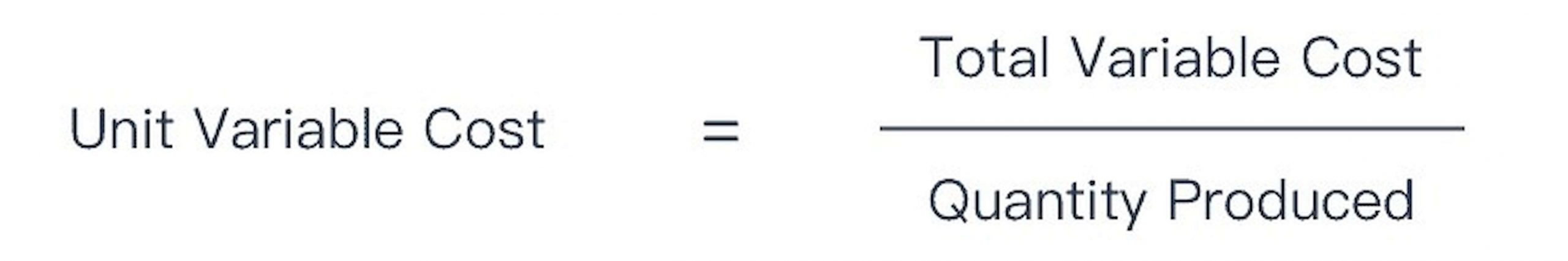

The formula to calculate both terms, however, is mostly the same for accounting purposes. Total WIP Costs are calculated as a sum of WIP Inventory + Direct Labor Costs + Overhead costs. Our mission is to empower readers with the most factual and reliable financial information possible to help them make informed decisions https://www.bookstime.com/ for their individual needs. Our goal is to deliver the most understandable and comprehensive explanations of financial topics using simple writing complemented by helpful graphics and animation videos. Learn more about Rootstock Financials by visiting the product page and watching a webinette about Rootstock financials.

Reporting capabilities

Then, train a tech-savvy leader from each function to use and champion the new system. Gather their feedback and implement it into the new system to provide a completely optimized solution come company-wide rollout. Creating a winning customer experience helps them sell more now and manufacturing accounting in the future. An ERP can unify all your sales touchpoints to help you create a consistently great experience no matter how customers engage with your brand. There are endless possibilities regarding how a manufacturing ERP’s forecasting capabilities can benefit your business.

Choosing the Right Manufacturing Accounting Software

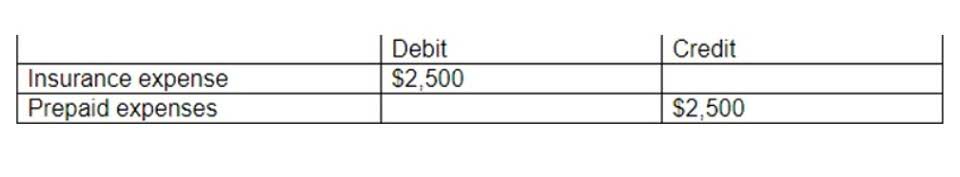

In this guide we’ll walk you through the financial statements every small business owner should understand and explain the accounting formulas you should know. Tickmark, Inc. and its affiliates do not provide legal, tax or accounting advice. The information provided on this website does not, and is not intended to, constitute legal, tax or accounting advice or recommendations. All information prepared on this site is for informational purposes only, and should not be relied on for legal, tax or accounting advice.

- These different methods can impact inventory costs and COGS as raw material prices or markets fluctuate, especially for longer manufacturing processes.

- Your manufacturing business is as creative and unique as you are, so it goes without saying your accounting software should be too.

- WIP inventory figures are useful information to measure metrics related to the production process.

- A real-time inventory tracking system can minimize the manual accounting tasks common in properly valuing inventory.

- Maintaining accurate and organized records of all the transactions and costs involved in production can be incredibly laborious if you do it manually.

Software for established businesses looking for greater efficiency, flexibility, and insight. Inventory is continually being sold and restocked, so you may need to make a cost flow assumption. It helps if you break down product costs from all the contributing factors that play a part in the cost of the manufacturing product – not only for each item but for all the activities that add cost to the end product. Lean manufacturing is all about minimizing waste while maximizing productivity. It is a practice first initiated by Toyota but has influenced manufacturing for decades, particularly the automobile industry.

Production Costing Methods

- Efficient cost management in manufacturing is like having a well-oiled machine; it keeps everything running smoothly and ensures enough money in the bank to keep the lights on and machines running.

- Its Product Footprint Management further helps manufacturers reduce greenhouse emissions.

- An ERP system offers features any company can use to integrate all of its functions and technologies, then collaborate across the company for greater efficiency and visibility.

- The cost of goods sold Manufacturing account tracks information on all inventory items sold by the firm.

- Manufacturers looking to streamline and improve every aspect of their distribution processes should consider Epicor Prophet 21 ERP.

Comentarios recientes